The production of high quality and resistant laminated glass requires a series of steps and conditions that must be met to successfully bind the different layers of material in a seamless and attractive way. The lamination process is carried out with machines that subject the glass and interlayer to certain heat and pressures to achieve their impeccable fusion and permanent bond. The interlayer we use is Kuraray by Trosifol PVB. Our most common laminated glass thicknesses are 5/16, 7/16, and 9/16.

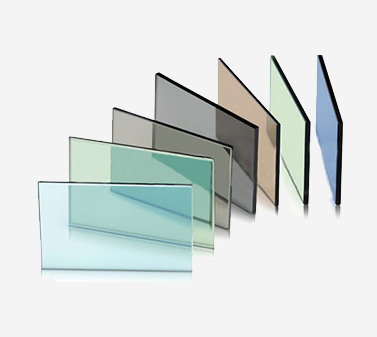

A wide variety of glass colors and textures are available to produce the most creative and

innovative products. Countless combinations can be made to achieve the most unique colors.

Kurary by Trosifol PVB is our interlayer of choice as it is a proven product, ensuring we meet all quality standards. A variety of interlayer colors and designs are available to create a one of a kind product.

LEARN MORE

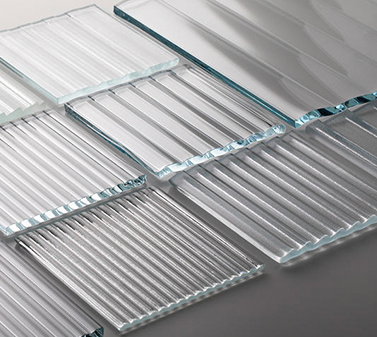

At Express Impact we work with many textured patterns that may be laminated to provide the benefits of safety glass with a modern touch.

LEARN MORE

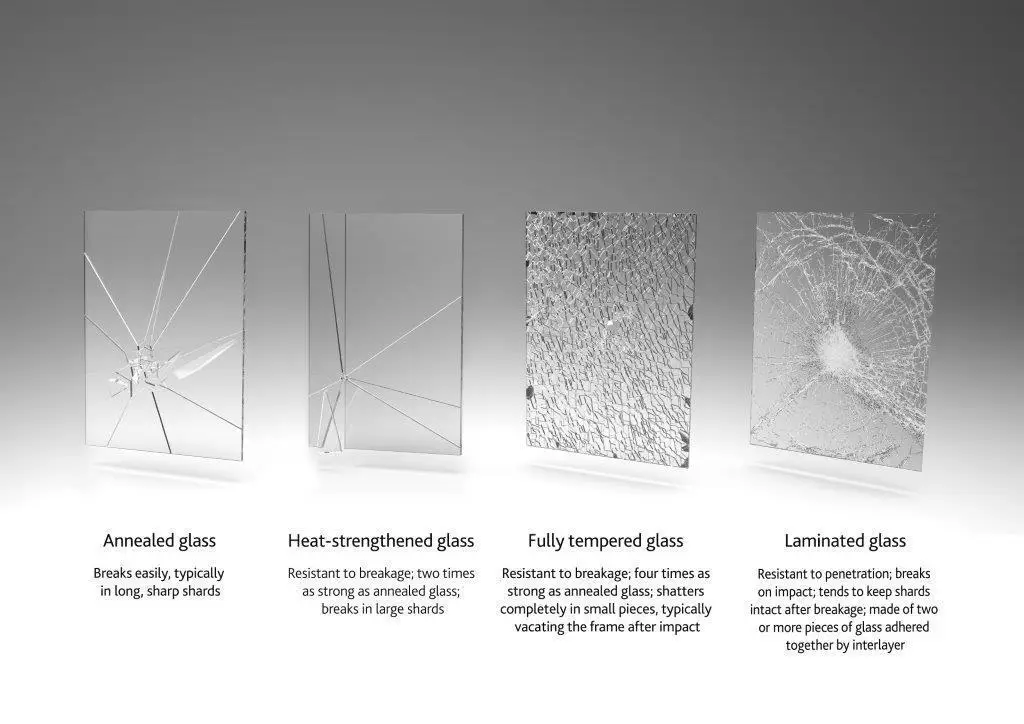

Laminated glass is a very versatile material with a wide variety of uses such as commercial and residential windows and doors, balconies, railings, staircases, elevators, partitions among many others. Annealed, HS, and tempered glass whether plain or textured can be laminated.

Laminated glass is highly sought after for hurricane and burglary protection. With the correct recipe and procedure, countless combinations of laminated glass are readily achieved. The glass may be colorless, colored, heat treated, coated, translucent, textured, etc. At Express Impact we are constantly thinking of ways to innovate and be more creative with our products. A variety of colored interlayers may also be used to achieve any desired design and shape. Our lead time in laminated glass is unmatched in the industry.

Contact Express Impact Manufacturing for more information on our products.