Glass is a mixture of key ingredients such as silica sand, soda ash, limestone and other ingredients depending on the final use and color. This mixture is melted at an extremely high temperature of about 3000 degrees Fahrenheit until liquified. This molten glass is stirred until all existing bubbles are removed. The molten is floated on top of liquid tin to shape and flatten the surface. Once the glass is cooled, float glass is made.

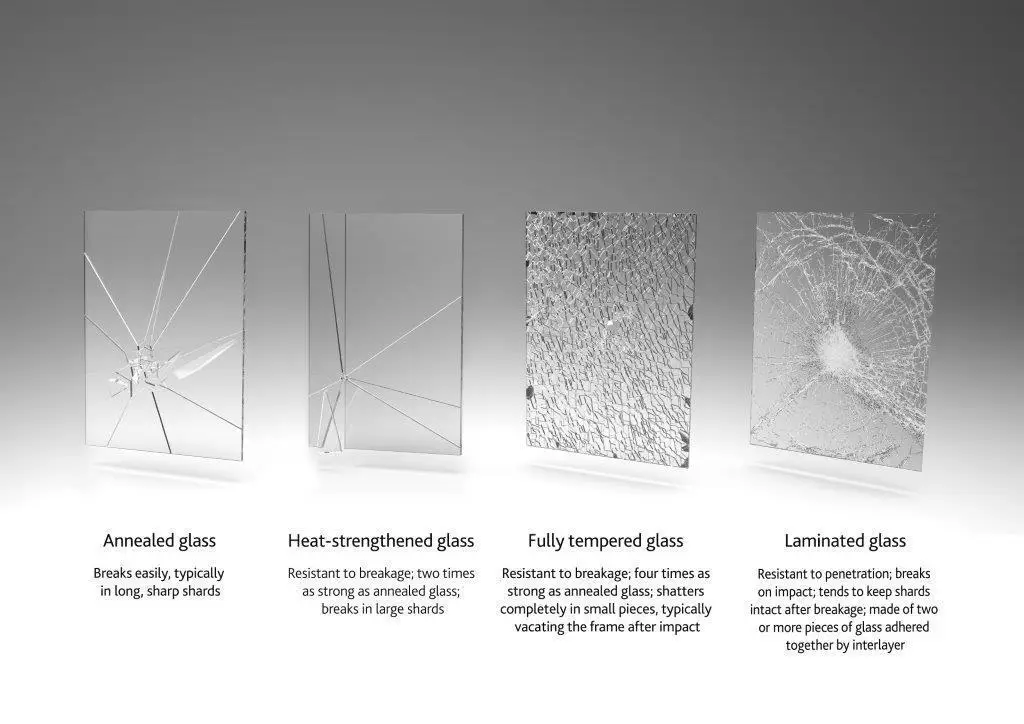

In order to achieve annealed glass there is a final crucial step, annealing. The glass is then heated to about 1000 degrees Fahrenheit removing the stress points formed while the float glass was cooling. Annealed glass can be further heat-treated and hardened resulting in heat-strengthened or tempered glass. Annealed, HS, and tempered glass can be laminated for maximum strength and protection.

Annealed glass or annealed laminated glass is commonly used in windows. Annealed glass alone can withstand temperature changes well and can be cut into different shapes and sizes as needed for any particular project. Laminated annealed glass can also withstand temperature changes and be cut while providing added protection as it is safety impact glass.

Contact Express Impact Manufacturing for more information on our products.